In the metal furniture industry, the quality of the paint finish is one of the key elements that determine the durability of a product. It is the correct preparation of the surface for powder coating that determines the corrosion resistance, the aesthetics of the product and its service life in everyday use.

One of the most modern methods used in industrial coatings today is zirconium technology - environmentally friendly, efficient and extremely effective.

Here are the most important facts and trivia about how we prepare the surface for powder coating at MALOW.

What is zirconium technology?

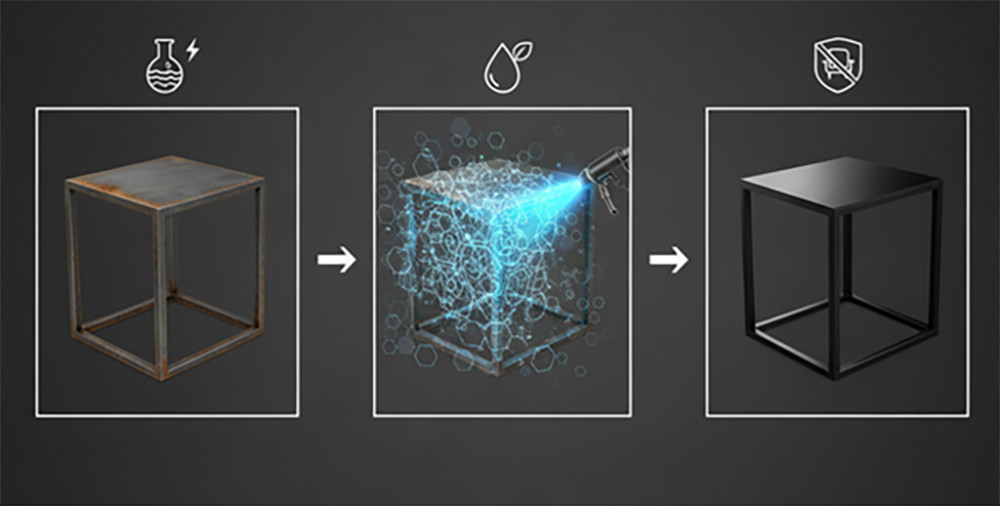

Zirconia treatment is a state-of-the-art chemical process that creates an ultra-thin, nanoceramic layer on the metal surface to increase paint adhesion and corrosion resistance.

In contrast to older methods:

- contains no phosphorus, nickel or chromium,

- works at a lower temperature,

- environmentally friendly.

It is the ideal solution for combining high-quality powder coating with an ecological approach and cost optimisation.

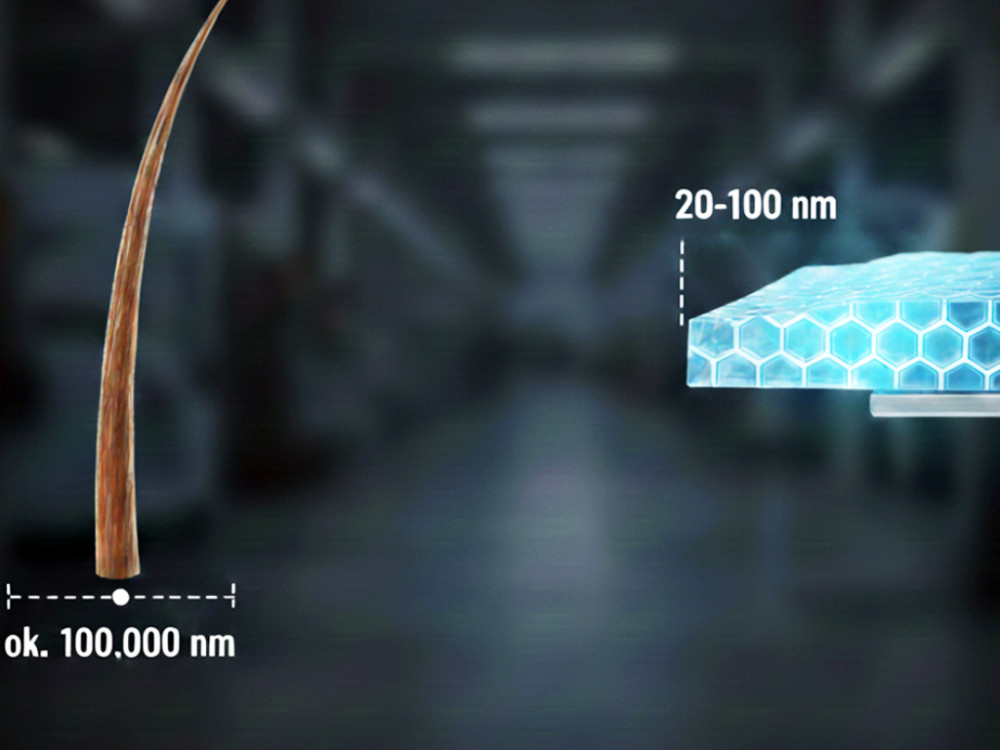

1. The zirconia coating is 1,000 times thinner than a human hair - and works more effectively

The zirconia layer is usually 20-100 nanometres in size, but nevertheless significantly increases the durability of powder-coated metal furniture

It is the microscopic ceramic structure that improves:

- corrosion resistance,

- adhesion of the powder coating,

- stability of the coating in NSS tests

2. Zirconia technology was developed as a response to stricter environmental standards.

In Europe, the use of heavy metals and phosphates is gradually being reduced. Therefore, zirconia technology has become a natural alternative.

It is:

- phosphorus-free,

- nickel-free,

- chromium-free,

- in line with MALOW's environmental policy.

This is particularly important with MALOW's strategy in line with its sustainability policy.

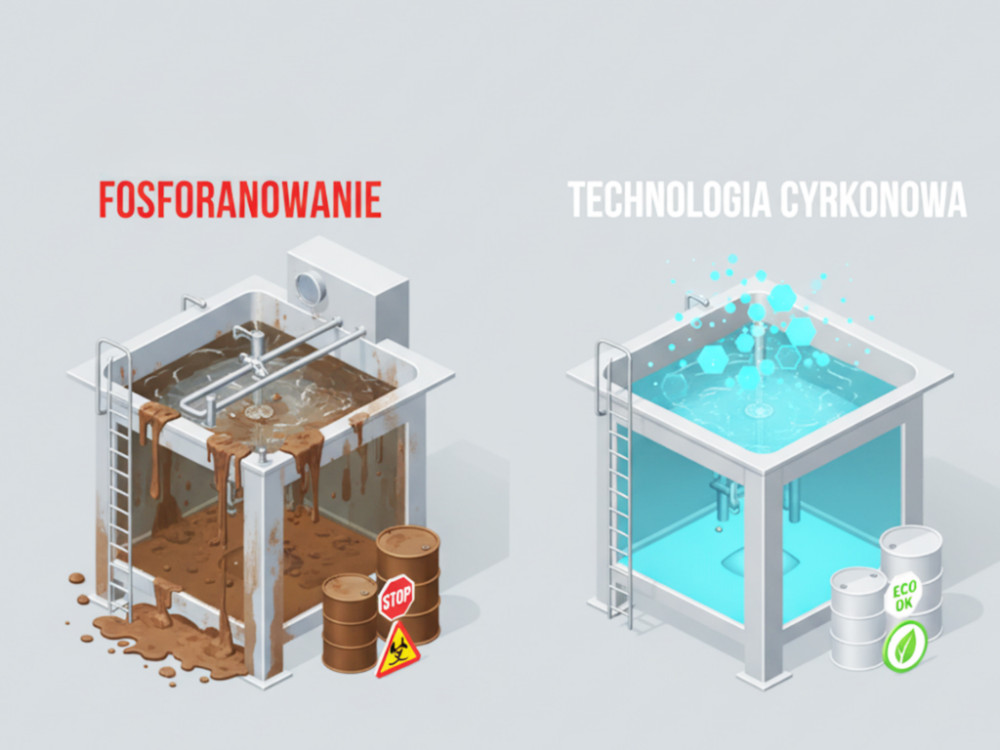

3. The zirconium process generates virtually zero sludge

Traditional phosphating produces a large amount of waste - sludge - which has to be stored, disposed of and removed regularly.

Zirconia treatment generates virtually no sludge, thus:

- reduces the risk of failure of the painting installation,

- reduces operating costs,

- increases process stability.

This is another reason why we have chosen this solution for our modern paint shops.

4. Zirconium saves energy and water

This is one of the most important arguments in favour of this process.

Compared to traditional surface preparation:

- uses 30-40% less energy,

- saves up to 50% water.

This is because:

- zirconium baths operate at temperatures of 20-30°C (phosphating requires up to 60°C),

- the number of rinses is lower,

- the process parameters are more stable over time.

This translates into lower production costs for metal furniture.

5. One process - many types of metal

Zirconium works very well with:

- black steel,

- galvanised steel,

- aluminium.

This allows us to prepare different parts in one process, which is very convenient and efficient - especially in batch and mixed production.

Summary:

Why use zirconium treatment in the production of metal furniture?

Zirconia technology is currently the most advanced and environmentally friendly method of surface preparation for powder coating.

It gives your furniture MALOW:

- gain higher corrosion resistance,

- have a more durable paint finish,

- are aesthetically pleasing and resistant to operating conditions,

- using more environmentally friendly and cost-effective technology.

This is the solution of the future - fully in line with sustainable production trends and market requirements.